Application Industry of Flip Mold Thermoforming Machine

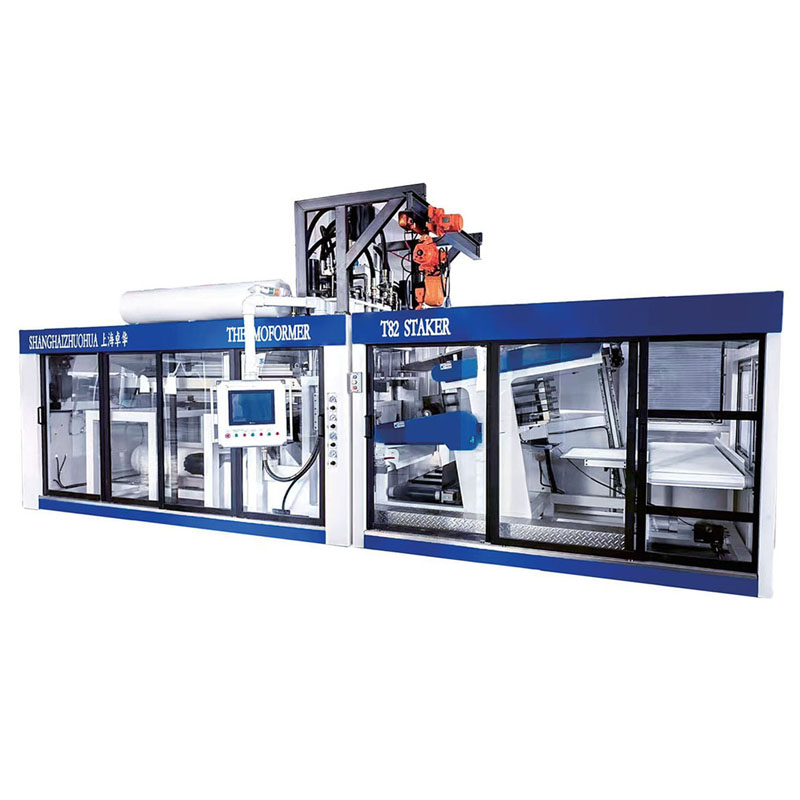

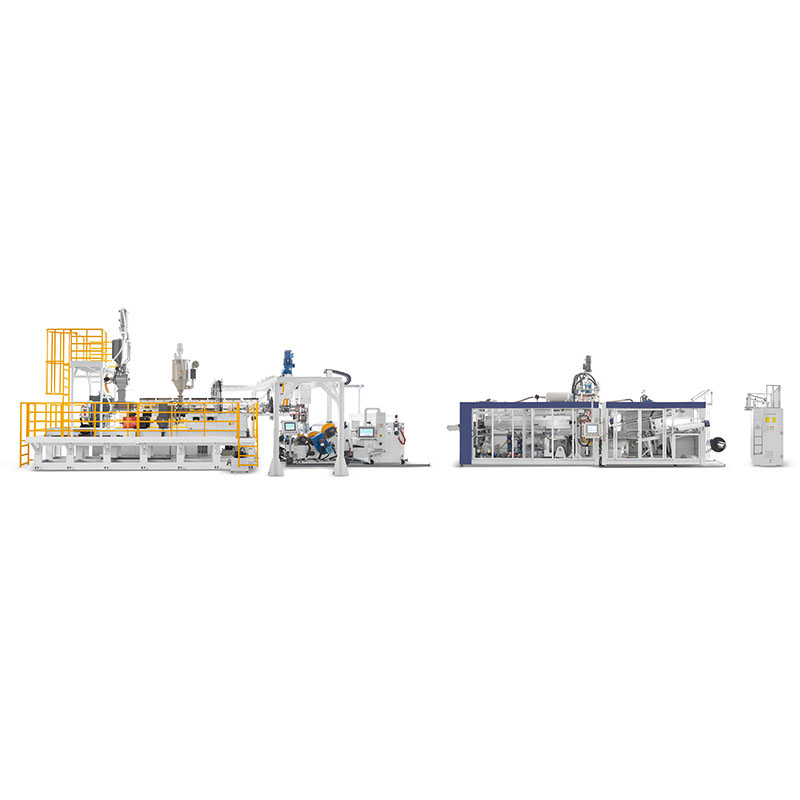

In today’s fast-paced manufacturing world, efficiency, precision, and automation are the pillars of success—especially in the packaging industry. Among the advanced technologies shaping this landscape, the Flip Mold Thermoforming Machine stands out as a powerful solution for producing high-quality plastic products across multiple sectors. Its unique mold-flipping mechanism, high-speed cycle performance, and consistent forming accuracy make it an ideal choice for businesses looking to scale up production without compromising on quality.

1. Food Packaging Industry

One of the most prominent applications of flip mold thermoforming machines is in food-grade packaging. The machine is widely used to produce items such as:

Disposable cups and lids

Snack trays and fruit containers

Microwaveable meal trays

Yogurt cups and clamshell boxes

Its hygienic production capability and compatibility with materials like PP, PS, and PET make it ideal for high-demand food packaging operations, where safety, shape precision, and sealing performance are essential.

2. Medical and Pharmaceutical Packaging

In the medical sector, the flip mold thermoforming machine plays a critical role in producing:

Blister packs for tablets and capsules

Sterile trays for surgical instruments

Single-use medical containers

With precise temperature and pressure control, it ensures secure and contamination-free packaging—an absolute necessity in the healthcare industry.

3. Consumer Goods Packaging

From electronic accessories to cosmetic kits, the consumer goods sector benefits from flip mold technology through:

Transparent clamshells

Plastic inserts

Retail blister packaging

The machine's ability to form detailed and uniform shapes enhances product presentation and shelf appeal, giving brands a competitive edge.

4. Industrial and Tooling Applications

Beyond consumer markets, the flip mold thermoforming machine is also used in producing durable trays and custom inserts for:

Toolkits

Automotive components

ESD (anti-static) packaging for electronic parts

Its robust forming capacity and adaptability to various sheet thicknesses make it a versatile asset in industrial production.

Conclusion

Whether it’s for food safety, product protection, or visual branding, the Flip Mold Thermoforming Machine has proven its value across diverse industries. As global demand for cost-effective and sustainable plastic packaging continues to grow, businesses equipped with this technology are better positioned to deliver precision, efficiency, and innovation—at scale.

For manufacturers seeking to upgrade their packaging line or enter new markets, investing in flip mold thermoforming technology is more than a choice—it's a competitive advantage.